Update

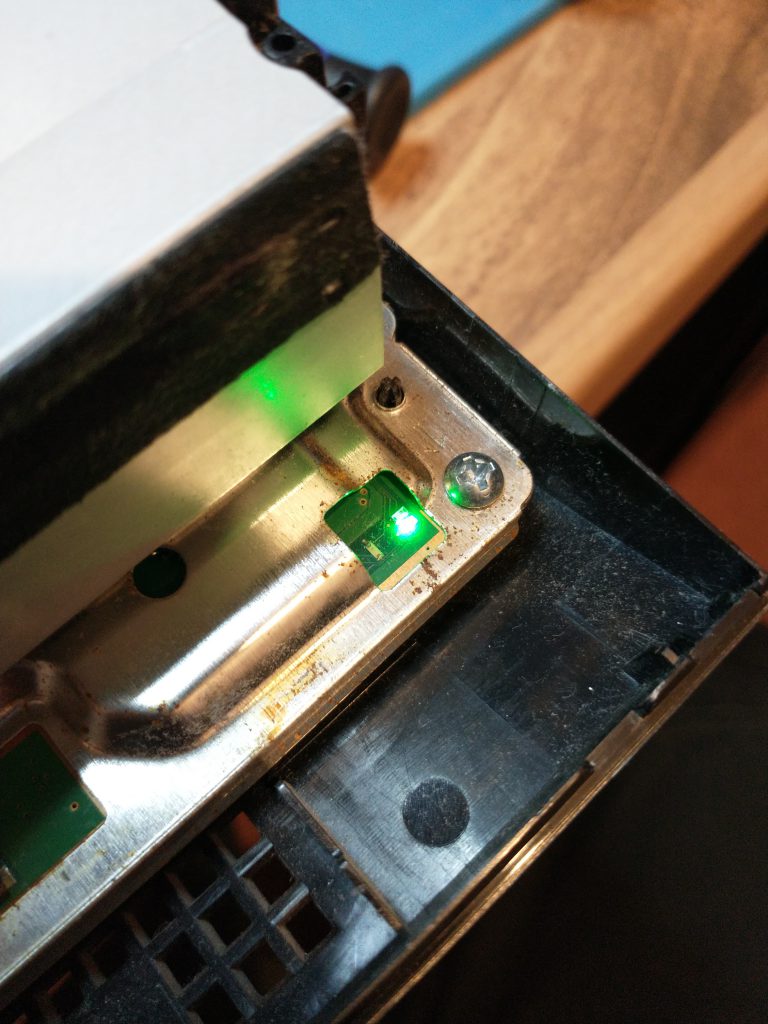

After swapping out diode D1 the system will now play games. Excellent. Almost.

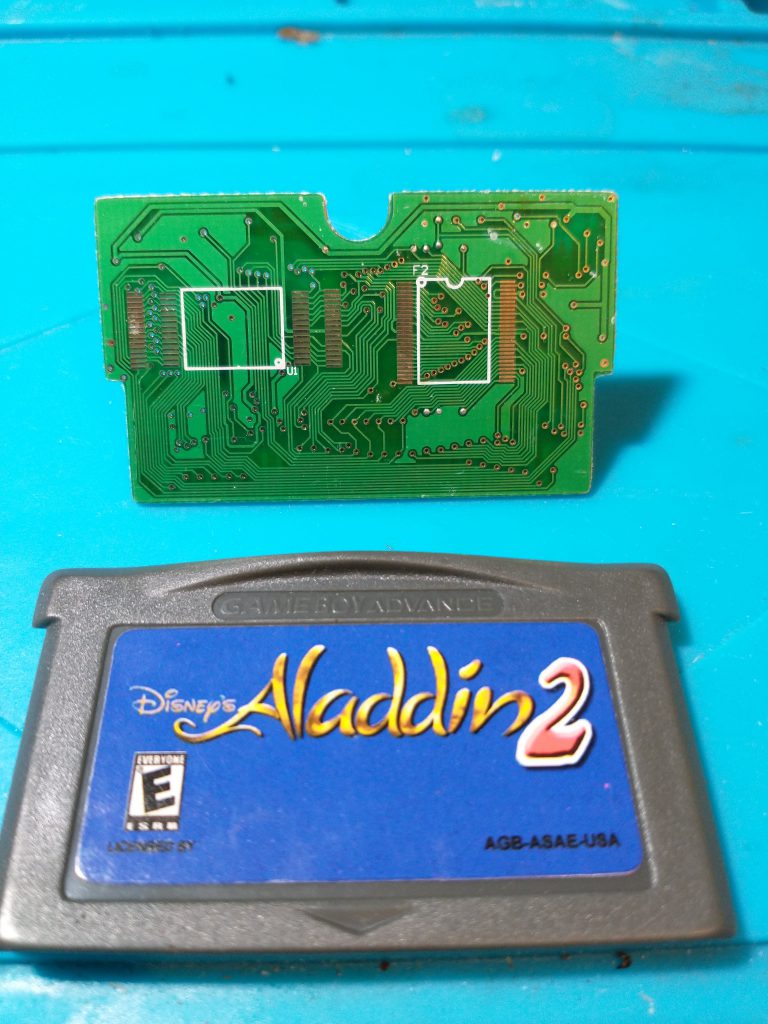

For some reason GT Championship is refusing to run. The game plays on my other systems fine. So it’s either a problem with the game cart and the game slot connector or there is still something wrong with the system.

The only way to check is to buy another version of the same game. So I did just that and it also refuses to play.

GT Championship must be addressing something on the CPU or RAM that the other games I have do not.

I narrow the fault down to a short on RAM pins 32 +33 which go to CPU pins 79 + 78.

Lifting pin RAM 32 and CPU pin 78 and joining them with a piece of jumper wire, clears the short and the game loads successfully. Excellent.

Initial Diagnosis

So I picked up a boxed Nintendo GBA Arctic Blue model recently with some signs of battery spit (corrosion) on the terminals.

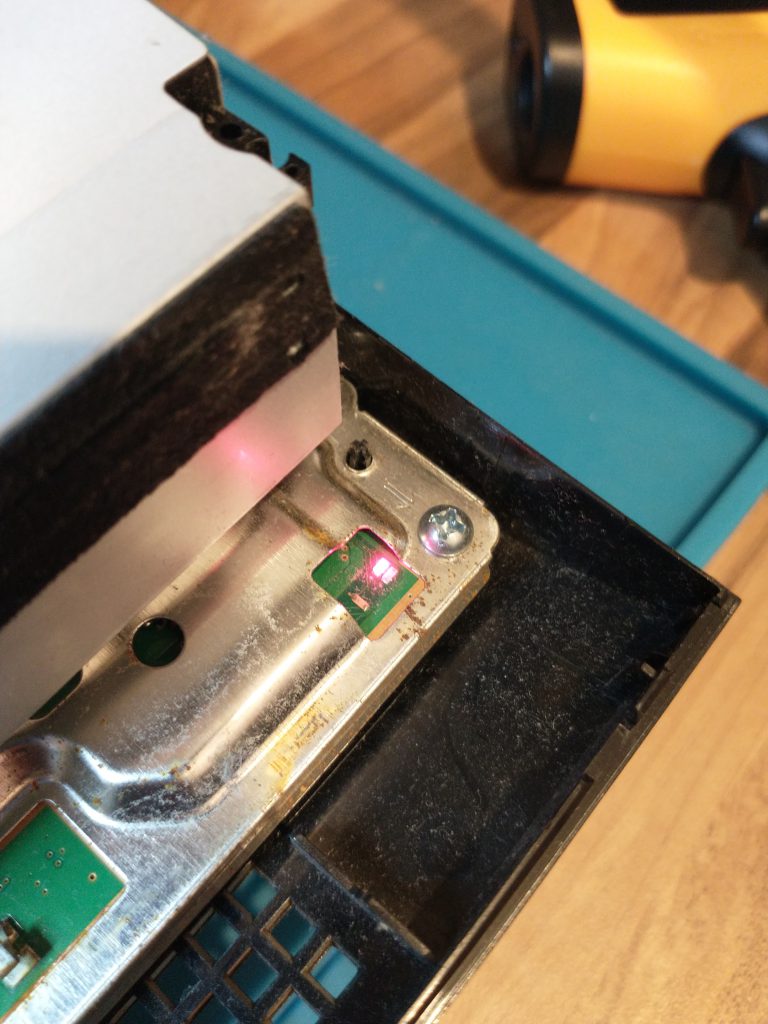

Sadly the rot had spread through to the switch which will need replacing. I can jump the switch and power the system using my bench PSU.

The booting up ping sound can be heard but there’s no display. Sadly I jumped to the conclusion that the display must be faulty. I tried an old display which also didn’t come on, which I assumed must be faulty too.

When trying to prise out the original screen from the front of the shell, I broke it completely. The only other thing I could do was to open a known working console and try that screen.

The working screen refused to dispaly too. It dawned on me the problem was with the board and it’s likely there was nothing wrong at all with original screen until I physically broke it. Gutted.

Fault Finding the GBA screen issue

Using my working board and a schematic I noted the voltages on the appropriate pins. Please note these are for the 40 pin connector (not the 32 pin).

Voltages on 40 pin screen connector

- 30: -0.9v

- 31: -13v

- 32: -0.pv

- 33: 13.4v

- 34: 4.9v

- 37: 2.5v

- 38: 2.3v

- 39: 2.1v

- 40: 2.08v

The faulty console is missing 13.4v on pin 33.